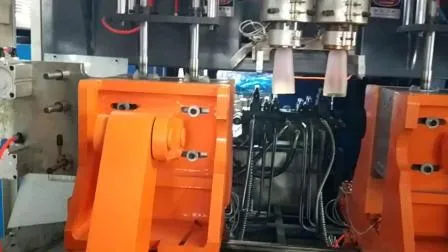

PE HDPE Detergent Cleaning Products Plastic Bottle Blow Molding Machine

Package size per unit product 540.00cm * 380.00cm * 220.00cm Gross weight per unit product 1300.000kg COMPANY PROFILE To;

Basic Info

| Model NO. | TVHD-5L-1 |

| Warranty | 1 Year |

| Type | Extrusion Blow Molding Machine |

| Raw Material | HDPE |

| Making Method of Parison | Extrusion-Blow Molding |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| After-sales Service | Have |

| Weight | 21 Ton |

| Transport Package | Water Proof Film or Standard Wooden Package |

| Specification | 4.6*5*2.3 |

| Trademark | TONVA |

| Origin | Zhejiang(Taizhou) |

| HS Code | 8477301000 |

| Production Capacity | 700sets/Year |

Packaging & Delivery

Package size per unit product 540.00cm * 380.00cm * 220.00cm Gross weight per unit product 1300.000kgProduct Description

COMPANY PROFILETonva was established at 1993. The company is one of the largest manufactures of Extrusion Blow Molding Machine, Stretch blow molding machine and kinds molds in China.

The Company has a group of experienced people who contribute more than twenty years in Blow Molding Machine industry and a team who good at after-sale service. We has passed the ISO9001:2015 International Quality Control System and the CE&SGS system. Moreover, since the company focus on innovation and invest in the advanced technology year after year, it been named the National High-Tech Enterprise in the year of 2014. With fabulous reputation and favorable service, our products reach great sales both in domestic market and more than 100 countries.

TONVA Extrusion Blow Molding Machine can be divided into Smart series, Standard series, Accumulator type large series. The range of the capacity is from 3ml to 3000L. They are suitable for Various materials, as PE,PP,PVC,PS,EVOH,EVA etc. They are used to produce various kinds of plastic products, such as oil barrel,Sprayer barrel,cosmetics bottle,pharmaceuticals bottle,food package,plastic toys,Christmas ball,plastic experimental apparatus and auto-parts etc.

Based on different functions, TONVA Extrusion Blow Molding Machine has various of function for clients products optional: such as Parison controller for bottle area wall thickness control, Co-extrusion of multiple layers, view line strip device, up&down device, filter and deflashing device.

Thanks to our customers' continued trust and support, we are able to export almost 300 sets machine each year to over 80 countries, like Bangladesh, India, Pakistan, South Africa, Malaysia, UAE, USA and so on. We cherish every opportunity you give us to do your product, aiming at win-win cooperation.

MACHINE INTRODUCTION

| Basic Information | |

| Blow molding type | Extrusion Blow Moulding Machine, TVHD-200ml-8 (1-10 die head, double station, purely hydraulic system) |

| Mould Cavity | 1-4cavity(optional, based on product's shape and weight) |

| Bottle volume | 50ml-5000ml |

| Power supply | 380VAC,50HZ(depending on clients' countries) |

| Applicable materials | pe/pp etc |

| PLC and HMI | Adopt PLC to control the action program of the whole machine; adopt HMI for communication, parameter setting, modification and picture display |

| Mode of cooling | adopt water cooler for the processing zone, fan cooler for the rest of zones |

OUR SAMPLE ROOM

PACKING & DELIVERY

Welcome to contact us for more info : )

You may also like

Send inquiry

Send now