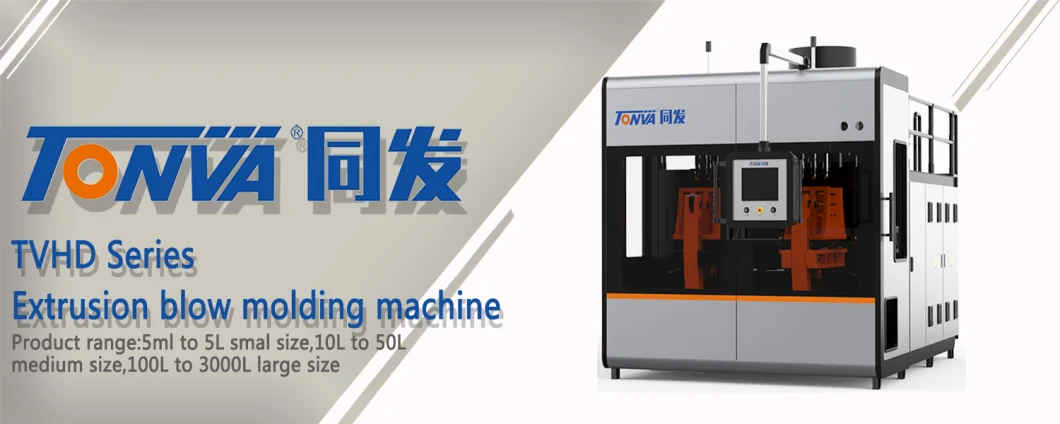

Tonva Child Toy Ocean Ball Blow Molding Machine

TONVA (A-Z turnkey supplier, 1993), guided by ISO9001:2008 International Quality Control System and CE & SGS certific at;

Basic Info

| Model NO. | TVHD-2L-6 |

| Certification | CE, ISO9001:2008 |

| After-sales Service | One Year |

| Model | Customized |

| Color | Customized |

| Voltage | According Customer Request |

| Transport Package | International Packing |

| Specification | 3.1*2.0*2.0 |

| Trademark | TONVA |

| Origin | Zhejiang, China (Mainland) |

| HS Code | 8477300000 |

| Production Capacity | 600 Sets/Year |

Product Description

TONVA (A-Z turnkey supplier, 1993), guided by ISO9001:2008 International Quality Control System and CE & SGS certific ation, has always been on the road of developing innovative high-end products and new technologies. Our business activities cover the manufacture of Blow Molding Machine, Pet Blow Molding Machine and Moulds. We are able to export almost 600 sets of machine each year to over 100 countries, like Bangladesh, India, Pakistan, South Africa, Argentina, Malaysia, UAE, USA and so on.Our extrusion blow molding machine is widely applied to daily-use products, sport water bottle, pesticide bottle, medicine bottle, cosmetic bottle, food packing container, furniture parts, auto parts, toy, jerry can and other small or medium-sized hollow plastic products.

Constant back-up support is our best service tool. In every phase of your project, we are here to offer technical advice. Your satisfaction at the purchasing experience is a great acknowledge to us. We are also committed to fulfilling your production efficiency to the utmost with the goal of win-win cooperation.

| Type: Extrusion Blow Molding Machine | Application: plastic bottles etc |

| Model: TVHD-2L | Material: PE,PP etc |

| No. of station: 2 | No. of cavity: 1-6 |

| Performance Characteristics: 1.It is suitable for the production of plastic hollow products of PE, PP,EVOH,AD and other materials; 2.PLC+HMI,Chinese / English and other language operation interface; 3.According to the characteristics of different plastics, different screw and die mandrel and runner style can be designed; 4.The double proportional valve controls the flow rate and pressure of the oil passage, the reversing valve controls the flow direction, and the brake of the deceleration valve is smooth and quick; 5.The toggle-type clamping structure is designed by the front and back colleagues of the template center to ensure the uniformity of the clamping force; 6.Automatic lubrication system, automatic alarm function, pay more attention to user experience. 7.Center feeding extrusion,no blind angle,fast color and material changing | |

Packing

About Us

| Main Business | Company | Core Values |

1) Extrusion blow molding machine, 3ml-5000L blow molded products 2) Blowing mould & Injection mould

| 1) Set up in 1993 2) Run business home and abroad 3) Own machine workplace and mould plant 4) Provide turn-keys system | 1) Competitive and experienced 2) Focus on specific needs of customer 3) Global after sales service 4) Brand new and efficient machinery 5) Deep knowledge of blow moulding process |

ServiceCertificationExhibition

You may also like

Send inquiry

Send now