Moair Mde90da Energy Saving Two Stage Two Driven Pm Motor Screw Air Compressor

Basic Info

| Model NO. | MDE90DA |

| After-sales Service | Online and Onsite Available |

| Warranty | One Year After Shipment. Except Vulnerable Parts |

| Lubrication Style | Oil-less |

| Cooling System | Air Cooling |

| Power Source | AC Power |

| Cylinder Position | Vertical |

| Structure Type | Closed Type |

| Installation Type | Stationary Type |

| Type | Twin-Screw Compressor |

| Airend | Torindrive |

| Color | Grey |

| Performance | Energy Saving Grade 1 |

| Working Pressure | 7-12.5bar |

| Free Air Delivery | 18.5-23.5m3/Min |

| Inspection | Online Inspection Available |

| Mute | Not Mute |

| Drive Mode | Electric |

| Starting Mode | Frequency Inveter |

| Certificate | CE, ISO |

| Advantage | Energy Saving |

| Transport Package | Export Standard Package |

| Specification | CE |

| Trademark | Moair |

| Origin | China |

| HS Code | 8414809090 |

| Production Capacity | 500units/Month |

Product Description

Moair MDE90DA Energy Saving Two Stage Two driven PM motor Screw Air Compressor

Product Description

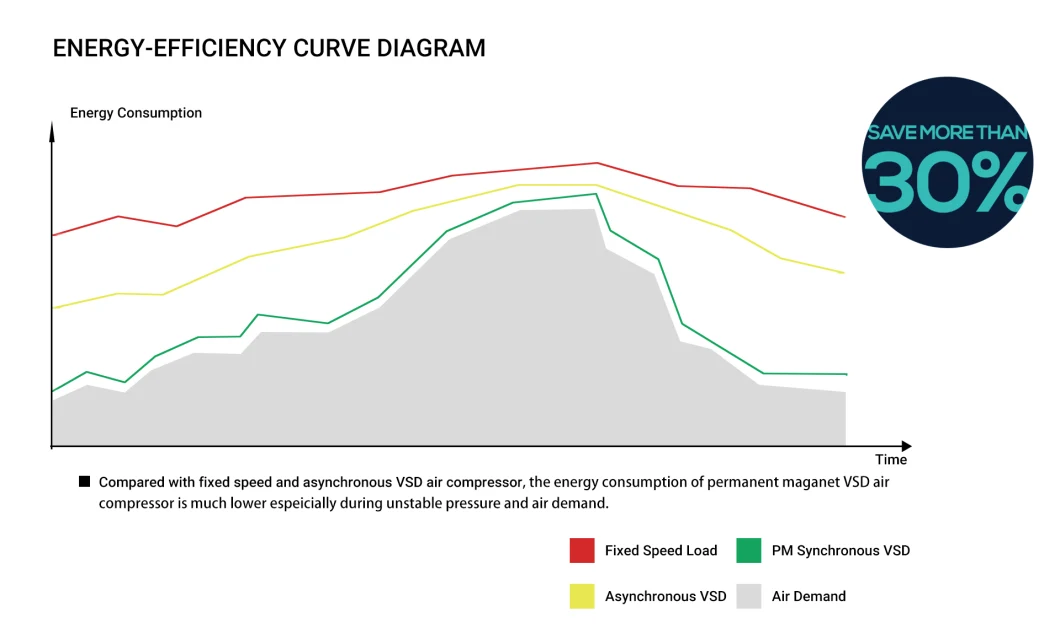

The MDE series two stage rotary screw air compressor with double permanent magnet motor drive is equipped with a double motor, double drive and double screw, which has the advantage of high efficiency, large starting torque and low noise. The main power range is from 45kw to 110kw, the pressure range is from 6bar to 10bar and the air flow range is from 9m3/min to 26m3/min.

Core componentsMotor- More stable: no mechanical transmission troublesThere is no gear shaft in the air compressor and the effective permanent magnet motor and the male rotor are directly connected on one shaft without gear drive, which can eliminate pitting of gear or hidden troubles of tooth fracture.Without shaft coupling, two integrated PM motors directly drive two airends of the air compressor, avoiding the hidden troubles of shaft coupling failure.

- More energy-savings: the airend is always in a smooth running stateThe two stage 3 phase permanent magnet rotary gear screw air compressor of MOAIR is powered by two independent PM motors and two independent inverters, which is intelligently controlled such as keep the airend running at a best level-pressure point by controlling discharge pressure and interstage pressure under the circumstance of different rotary speed and different pressure. The best running speed of air compressor can be automatically calculated while running and then the compression ratio can be balanced by final match, which can keep the compressor in a best running state, thus obtaining the highest efficiency.

- More effective: high-efficiency permanent magnet motor and no gear drive loss.With a motor of a high protection degree of IP54, it is more energy-saving and it can stay effective at low frequency and low speed.

- More environment-friendly operation with lower noiseNo noise of motor bearings, gear meshing and coupling transmission.

- More structure-compactThe volume of PM motor is small and the structure is compact, which can save much space.

- Change the traditional induction motor with high-efficiency technology of permanent magnet rotary screw motor, thus reducing the consumption in transmission.

- Powered by two independent PM motors and two independent inverters, the compressor is intelligently controlled such as keep the airend running at a best level-pressure point by controlling pressure of air flow and interstage pressure under the circumstance of different rotary speed and different pressure. The best running speed of compressor can be automatically calculated while running and then the compression ratio can be balanced by final match, which can keep the compressor in a best running state, thus obtaining the highest efficiency.

- Because the gear ratio is fixed, point efficiency is emphasized in this case. That is to say, only with fixed rotary speed and rated pressure did it have the best specific power. When running in a state of variable speed and variable frequency, considering the fixed speed of gear, interstage pressure will not reach the best one. Rotational speed declining while energy consumption not declining at the same time, it is not suitable for running in variable speed and variable frequency state.

Company Profile

Q1: What 's your factory addressA2: Our company is located in NO.88 Yiyu Road, Changshu, Jiangsu, ChinaQ2: How long is our deliveryA2: Our standard delivery time is 20-30 days after confirmation order & receiving recipets for standard compressors, for the other non-standard requirement can discussed case by case.

Q3: Can you accept OEM orders? A3: Yes, with professional design team, OEM orders are highly welcome.