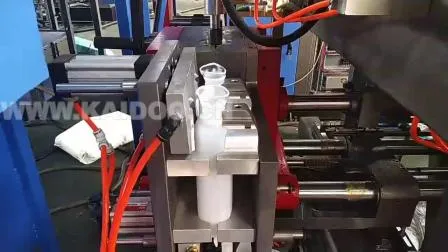

Manual Plastic Pet Stretch Blow Moulding Machine

manual plastic PET stretch blow moulding machine 3000-3300 bottles/hour, max: 0.6L, 3 Cavity ZQ-A series, newly develope;

Basic Info

| Model NO. | ZQ-A600-3 |

| Certification | CE, ISO9001:2008 |

| After-sales Service | Engineers Available to Service Machinery Overseas |

| Special for Max Volume | 600ml Pet Bottle |

| Number of Cavity | 3 Cavities |

| Products Output | 3000-3300bph |

| Delivery Date | 30 Days |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | General Packing |

| Specification | 200-600ml |

| Trademark | ZIQIANG |

| Origin | Huangyan, China |

| HS Code | 8477300000 |

| Production Capacity | 40 Sets/Month |

Product Description

manual plastic PET stretch blow moulding machine3000-3300 bottles/hour, max: 0.6L, 3 Cavity

ZQ-A series, newly developed by our company, is a two-step automatic blow-molding machine, which requires labor to put performs into the preheater only. ZQ-A series is of one cavity and the maximum cavity of the bottles is 0.6L, 2.0L, 5L. It can blow various bottles in shapes: Carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET, PP etc.

Compared with other full-automatic series, ZQ-A series has no automatic conveyer, so it can't transfer performs automatically, but requires labors to put performs into preheater. The distinctive feature of the ZQ-A is as follows: It has saved the cost to the maximum extent; It has lower rejection rate, higher production, and more stable performance than the semi-automatic one, and moreover, it is easy to run. Therefore, it will take the place of the semi-automatic blow-molding machine.

manual plastic PET stretch blow moulding machine. Machine info.

| TYPE | ITEM | ZQ-A600-1 | ZQ-A600-2 | ZQ-A600-3 |

| CONTAINER | Number of cavity | 1 | 2 | 3 |

| Output | 1100-1400 pcs/hr | 1700-2300 pcs/hr | 3000-3300 pcs/hr | |

| Max.container volume | 0.6L | 0.6L | 0.6L | |

| Max.neck diameter | 38mm | 38mm | 38mm | |

| Max.container diameter | 60mm | 60mm | 60mm | |

| Max.container height | 260mm | 260mm | 260mm | |

| ELECTRICAL SYSTEM | Number of lamp | 14pcs | 28pcs | 32pcs |

| Max.heating power | 9kw | 22kw | 32kw | |

| Installation power | 12kw | 25kw | 35kw | |

| Actual power consumption | 9kw | 14kw | 20kw | |

| AIR SYSTEM | Operatating pressure | 7kg/cm² | 7kg/cm² | 7kg/cm² |

| Low pressure consuming | 800Ltr/min | 1000 Ltr/min | 1200 Ltr/min | |

| Blowing pressure | ≤30kg/cm² | ≤30kg/cm² | ≤30kg/cm² | |

| High pressure consuming | 1200-1600Ltr/min | 1500-2000Ltr/min | 2000-2500Ltr/min | |

| CHILLER WATER | Operating pressure | 5-6 kg/cm² | 5-6 kg/cm² | 5-6 kg/cm² |

| Temperatuer | 10°C | 10°C | 10°C | |

| Consuming | 3600kcal/hr | 5600kcal/hr | 7600kcal/hr | |

| Flow rater | 20Ltr/min | 30Ltr/min | 40Ltr/min | |

| MACHINE | Machine dimension | 2.5×1.4×1.7(m) | 2.9×1.55×1.8(m) | 3.4×1.4×1.8(m) |

| Machine weight | 1.5T | 1.6T | 1.9T |

!Note: Custom production accepted. Any client idea tried.

You may also like

Send inquiry

Send now