Semi Auto Machines for Manufacturing 3L Plastic Water Bottles Pet Wide Mouth Making Equipment Jar Stretch Blow Moulding Machine

Basic Info

| Model NO. | SA-1L-4/1 |

| Material | Pet Preforms |

| Certification | CE, ISO9001 |

| Delivery Time | 30~45days |

| Mould Material | #45 Steel |

| Language | According to Customers |

| Shipping Port | Ningbo |

| Output | 1500-1600bph |

| Bottle Volume | 0.1-1L |

| Neck Diameter | 28-80 mm |

| Low Pressure | 10 Bar |

| Voltage Supply | 380 V / 50 Hz |

| Installed Power | 14kw(22 Kw) |

| Weight | 500 + 440kg |

| Transport Package | Wooden and Film Packaging |

| Specification | 800BPH |

| Trademark | Sinotech |

| Origin | Jiangsu |

| HS Code | 8477309000 |

| Production Capacity | 1500-1600bph |

Product Description

SinoTech SA-20L-1 PET stretch blow molding machine is one of the newest products for our customer. Its strongest point is energy savings. Adopting high pressure clamping, automatic stretch blow molding machine makes self-adjustment in accordance with the different pressure needed during production, thus ensures the super clamping force. While the high pressure sealing system with automatic adjustment permits that mold sealing is under condition of 100% air tightness before blowing and avoid air energy loss owing to incomplete air tightness. With such effective control over air energy and power, it takes a big part to lower costs and improve efficiency.

1. Infrared lamps adoped in the pre-heater ensures PET preforms being heated evenly.

2. Mechanical-double-arm calmping ensures mould being tightly closed under hight pressure and high temperature.

3. Pneumatic system consists of two parts. pneumatic acting part and bottle blowing part in order to meet different requirements for both acting and blowing. It provides sufficient steady high pressure to blowing. It provides sufficient steady high pressure to bloww large irregular shape bottles.

4. Equipped with silencer and oiling system to lubricate the mechanical pars of the machine.

5. Operated step-by-step and in semi-auto made.

6. Wide-mouth jar and hot-fill bottles can also be made.

Detailed Photos

01 LCD-Touch ScreenEasy operation and control

02 Anti-Pinch device(Two button) to ensure safe production

03 AirTac Pneumatic valves,Equipped with Pre-blow, easy installation

04 Built-in low pressure converter,No need low pressure air compressor.Help customers save investment costs.

05 Heating Oven(Infrared heating tube),Preforms heating by Linear Lamp heating before bottle blowing.

06 Mould of Bottle, #45 steel with good quality of CNC manufacture,Customize by your request, Equip with Air cooling or Chiller

Product Parameters

| Item | SA-1L-4/1 |

| Output | 1300-1500BPH,Volume: 0.1-1l |

| Bottle volume | 0.1 - 1l |

| Neck diameter | 28-80 mm |

| Low pressure | 10 bar |

| Blowing pressure | 15 (up to 25) bar |

| Low and high pressure air demand | 1.2m³/min for bottle 1L |

| Cooling liquid temperature | 7-9 °С |

| Voltage supply | 380 V / 50 Hz |

| Installed power | 22 kW |

| Overall dimensions | 1870x720x1560mm(1pc) 1710x760x1810mm(1pc) |

| Weight | ~ 500 + 220 kg |

Production Process

Application

SinoTech SA-20L-1 PET stretch blow molding machine is widely used to produce varieties of PET plastic container and package for mineral water, beverage,oil, cosmetic and hot infusion, ect. Controlled by micro-computer with each main process fitted with safety of self-locking, it is operated by only one worker and the total production is completed automatically. Its wide utilization and reliable performance make it become popular and attractive to all bottle manufacturers.

Mold Display

- 1-Cavity 5 Gallon Blowing Mold

- 2-Cavity 5 Liter Blowing Mold

- 2-Cavity Automatic Blowing Mold(7075 Aluminum)

- 4-Cavity Automatic Blowing Mold(7075 Aluminum)

- 6-Cavity Automatic Blowing Mold(7075 Aluminum)

- Wide-mouth Jars Blowing Mold

Bottle Design

Company Profile

FAQ

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon

Q: Do you provide any spare parts with machine?

A: Yes, we offer all necessary spare parts together with machine sending and 3 days spare parts delivery after machine sale.(contact us for packing list )Q: How about your after-sale service?

A: We offer manual instruction and engineer training before loading, after shipment we provide 24 hours online support, video technical support or field installation assist

Q: What is the lead time?

A: We have standard model machine in stock.It can be delivery within 1 week. If need to make mould, the delivery time need half month after drawing confirmed

Q: What is the warranty period for your machine?

A: 12 months warranty for components and technical support

Q: Do you provide custom machines?

A: Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs

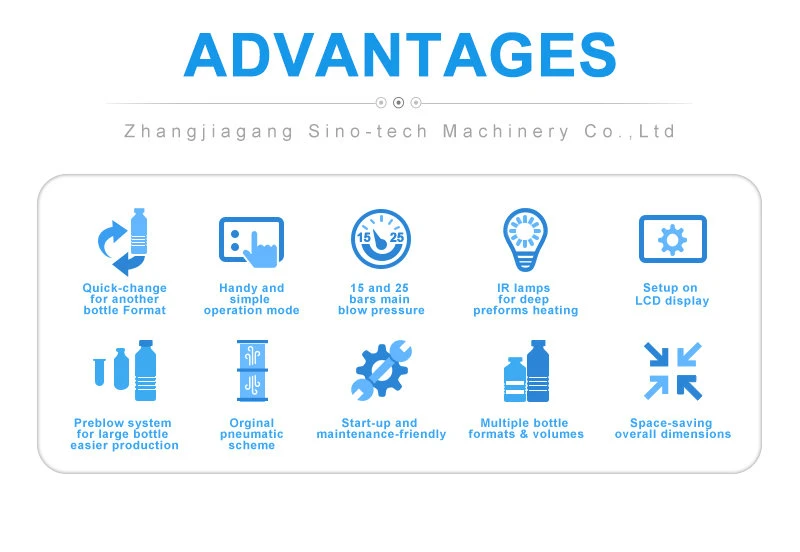

Q: What's the advantage of SINO-TECH?

A: We provide customers with turnkey projects. Including plant design, blow molding machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time for customer.

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.