High Output Plastic Bottle Making Machine / IBM 25 Injection Blowing Molding Machine Injection Blowing Machine Blow Molding Machine

Basic Info

| Model NO. | HL |

| Warranty | 1 Year |

| Type | Injection Blow Molding Machine |

| Raw Material | PE |

| Making Method of Parison | Injection Blowing |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| After-sales Service | Yes |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Automatic | Yes |

| Model Number | Hl |

| Product Name | Injection Blow Molding Machine |

| Color | Customer Choice |

| Material | PP, PS, PE, San, PMMA, PC, PETG, Pen and Other |

| Machine Type | High Speed Plastic Bottle Making Machine |

| Transport Package | Waterproof Membrane Cover and Wooden Box |

| Specification | different |

| Trademark | HL |

| Origin | China |

| HS Code | 8477302000 |

| Production Capacity | 2000-6000bph |

Product Description

injection blow machinery

Automatic Injection Blow Molding Machine (European)

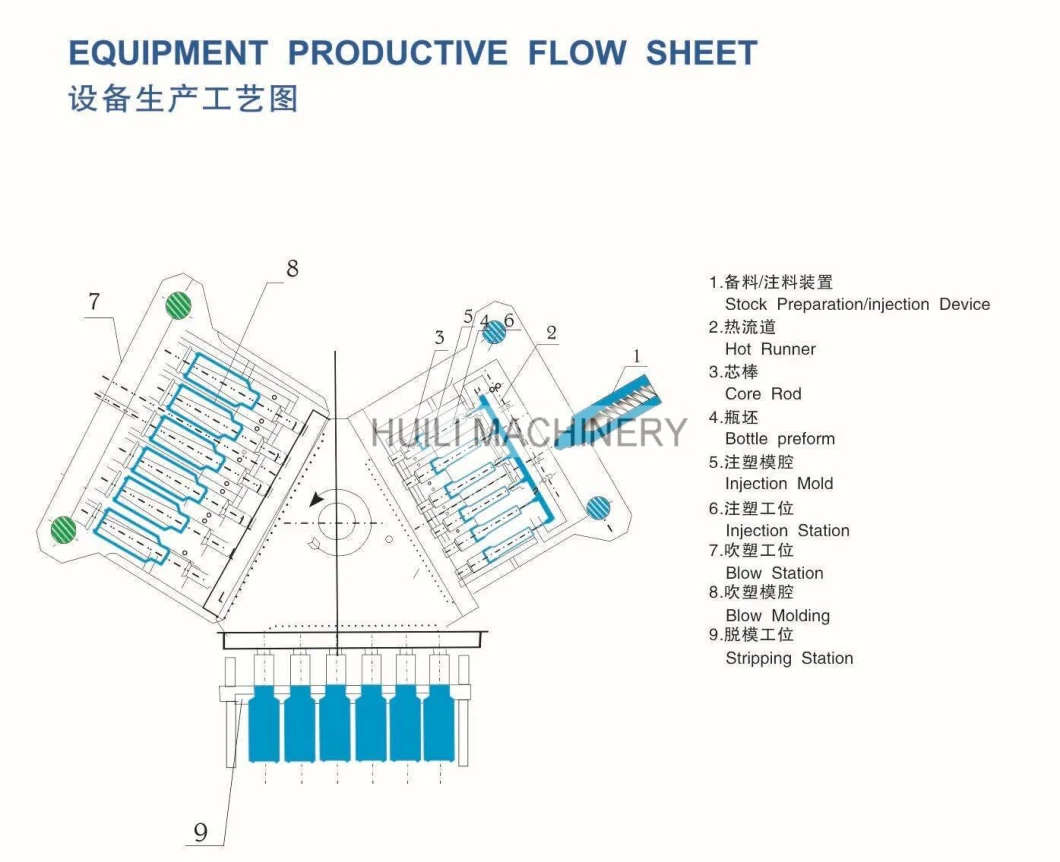

The machine is a full automatic injection molding equipment, suitable for processing PP, PS, PE, SAN, PMMA, PC, PETG, PEN and other thermoplastic, widely used in pharmaceutical, health care products, food and beverage, cosmetics, etc..One Mold with Multi-caivity for automatic continuous production technology, using three horizontal station rotary device, hot runner system and multi-stage injection molding system,injection molding, blow molding, demolding three position and action to ensure equipment of high efficiency and energy saving operation, ensure smooth product bottle, the bottleneck of inner and outer diameter and thread high precision, no waste is the standard equipment of modern enterprise environment-friendly production.

This machine has used the European standard injection blowing mode, which has absorbed the advantages of domestic injection.

Has the following characteristics:

Close mould cylinder, ensure product cleaning. The clamping force of the clamping force on the internalbalance, uniform.

Decreased the Machine height for easy assemble the mold.

Unique hydraulic servo system, reasonable layout of the pipeline, so that the machine is running high efficiency and energy saving.

The unique structure of the boost lock structure increases the clamping force and reduces the energy consumption of the system.

With servo system to control the mold rotary & increase rotary accurancy and reduce the dry cycle time.

Special double cylinder horizontal valve plate superimposed injection system, so that the injection, storage more smooth and fast, beautiful appearance, Special plastic components, to meet the requirements of different products, multi-level injection, pressure projection.

Internal layout optimization, equipment maintenance,maintenance more convenient.

Release the digital sensor detection, and increase the mandrel rotary detection function, realize the unattended, automatic operation.

Optional air conditioning mandrel function, shorten the product cooling cycle,solve the problem of sticking mandrel.

The conveyor belt can be connected with the visual inspection, Leakage Thester labeling and other equipment.

Final products photo

Equipment Flow Sheet

Related Machine

Extrusion blow moulding machine

Company Information

cooperated customer

Injection blow molding machines are packed with wooden pallets, covered with plastic film; auxiliary machines and spare parts are packed with wooden boxes. The loading to containers is done according to weight balance, every package's position is fixed in containers to avoid moving. The photos of whole delivery will be sent to you for reference.

For choosing proper machine and saving your time, please read below questions carefully and send your inquiry soon , thanks .

1.what material you will use(PP PE or PET ?)

2.weight for plastic product

3.pictures for plastic product (including dimension for plastic product)

4.what output per hour do you need ?

5.Other requirements about the machine you want.

Turnkey project service:

1. we will provide all the machines for the complete production according to customer's requirements.

2. we will provide complete service for factory layout and other information to help customer to build the factory.

3. we can also provide the raw material to the customer if you need.

4. we will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer. we are the professional and trustable supplier for turnkey projects. Let us do win-win business together.

By the way , Our company is about 110 km away from Shanghai(1.5 hour bus driving from shanghai airport) . Warmly welcome you to visit our factory at any time.