Automatic 5 Gallon Pet Water Bottle Making Machine Production Factory of Plastic Bottles Pet Blow Molding Machines Used

Basic Info

| Model NO. | YCQ-2L-8 |

| Type | Stretch Blow Molding Machine |

| Raw Material | PET |

| Making Method of Parison | Stretch Blow |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, QS |

| Output | 8000bph |

| Mould | 8 Cavity |

| Service | Full Technical Training |

| Driven Type | Electric |

| Color | Orange |

| Suitable | 0~2L Bottle |

| Heating Method | Electric Cycle Heating |

| Transport Package | Film Packing |

| Specification | YCQ-2L-8 |

| Trademark | DAWSON |

| Origin | Jiangsu Zhangjiagang |

| HS Code | 8477300000 |

| Production Capacity | 200 Sets Per Year |

Packaging & Delivery

Package size per unit product 3100.00cm * 3100.00cm * 2100.00cm Gross weight per unit product 10000.000kgProduct Description

DAWSON MACHINE & MOULD GROUPAutomatic PET Bottle Blow Molding Machine Q9000

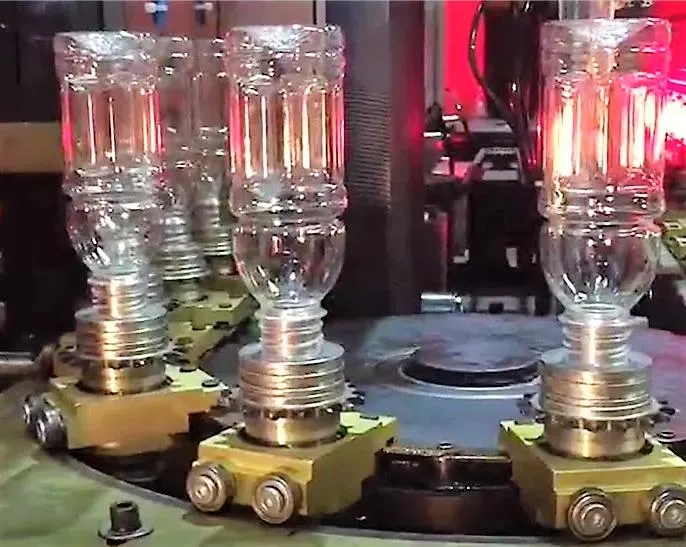

This PET water bottle blow molding machine is specially designed to produce water bottle,

PET bottle with high heat resistance for hot filling package such as juice and tea. It adopts multiple blowing to reduce the residual stress, as result shaped bottle has slight shrinkage during hot filling.

In addition, crystallization varies with different mold design, as a result, the PET bottle produced can stand temperature over 90°C depending on the type of PET material with different crystallization rate. The neck up blowing mode protects the bottle preform from damage during blowing and ensures stable

performance. With high strength, good transparency and low production costs, abundant material resource, PET Blow Moulding Machine plays a big role in hot filling package market.

Product Description

Fully-auto plastic bottle blow molding machine

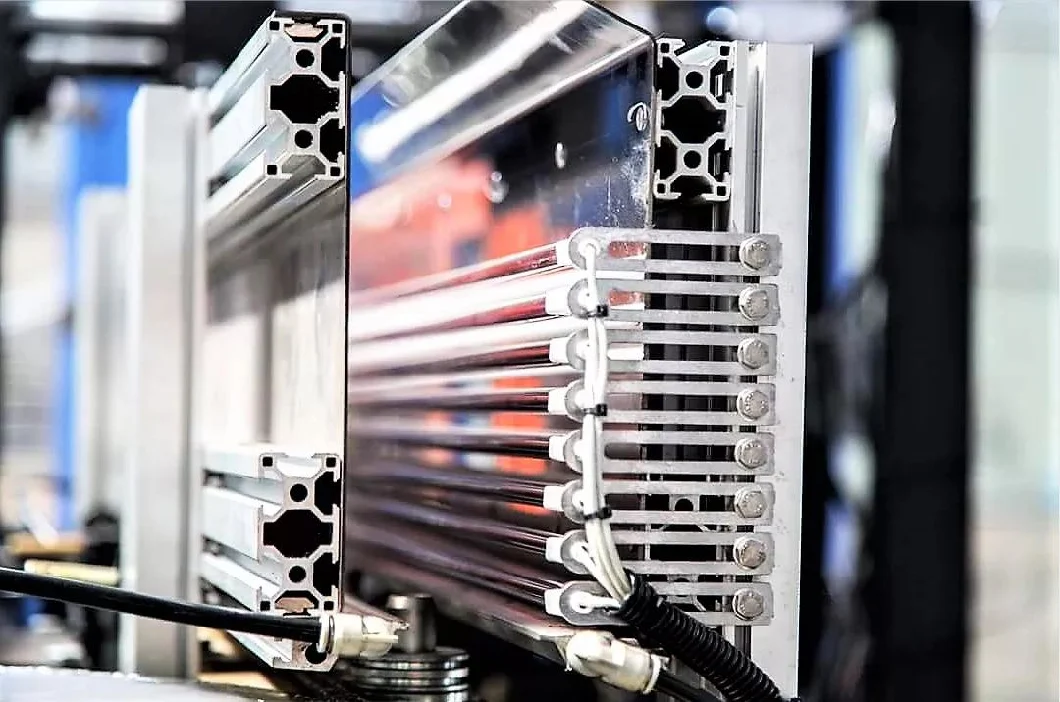

This PET bottle blowing machine used for the produce of PET water bottle, hot-fill bottle, CSD, drinking oil and pesticide bottleadopt servo control system,and structure are stable and reliable ,high -speed and smooth,easy maintenance.the equiped mold is very flexible which can meet the needs of non-stop inline produce. The touchable screen control and temperature adjustment simplified the temperature adjustment for different bottle blowing.Machine PartServo driving and cam linking blowing section: The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement,equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.Small performs distance heating system Heater distance in the heating oven is reduced to 38mm, compared with the conventional heating oven it saves more than 30%electricity consumption.Equipped with the air cycling system and redundant heat discharge system, it ensures the constant temperature of the heating zone. Efficient and soft perform inlet system By rotary and soft preform inlet system, the speed of preform feeding is ensured meanwhile, the preform neck is well protected.

Technical Parameters

| Item | Q6000 | |

Bottle type specification | Cavity | 4 |

| Theory output | 6000 | |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 28-38mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

Power specification | Light tube quantity | 40pcs |

| Light tube power | 1.5KW | |

| Maximum heating power | 60KW | |

| All electric machine installation | 65KW | |

| Actual consumption | 40%--70% | |

Air pressure specification | Work pressure | 7-9kg/cm2 |

| Low-pressure gas consumption | 1600L/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher -pressure gas consumption | 1500Ltr/min | |

Air pressure specification | Work pressure | 5-6 kg/cm2 |

| Temperature range | 10ºC | |

| Consumption | 6000kcal/hr | |

| Frozen water flow | 138L/min | |

Machine specification | Machine size | 4.5x2.0x2.3 |

| Machine weight | 4.5ton | |

Our service

FAQ |

Q: Can we visit your factory? Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support! |