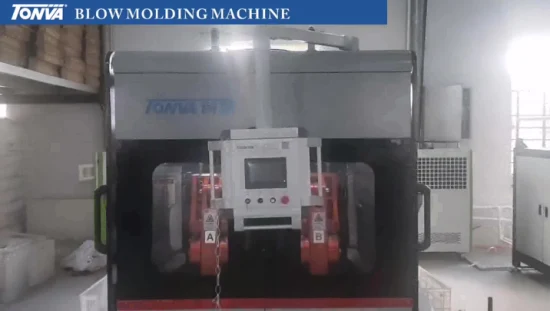

10liter/15liter/3gallon/4gallon/5gallon/18.9L/20L Large Water Bottles Semiautomatic Blow/Blowing Moulding/Molding Machine/Plastic Machinery/Plastic Machine

TS-20L stretch blow molding machine is specially designed to produce 5-gallon bottle and 20L wide mouth jar. Its output ;

Basic Info

| Model NO. | TS-20L |

| Type | Special Structure Bottle Blowing Machine |

| Automatic Grade | Semi-Automatic |

| Warranty | 1 Year |

| Raw Material | Pet |

| Making Method of Parison | Stretch Blow |

| Automation | Non-Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, QS, UL, GMP |

| Transport Package | Wooden Case |

| Specification | TS-20L |

| Trademark | TAISO |

| Origin | China |

| HS Code | 8477309000 |

| Production Capacity | 50sets/Month |

Product Description

TS-20L stretch blow molding machine is specially designed to produce 5-gallon bottle and 20L wide mouth jar. Its output is up to 90 BPH for 5-gallon bottle and even could reach 120 bottles per hour in certain case. BS-60 consists of main unit and rotary infrared heater. The ordinary quartz lamp cannot heat preform ideally because the preform wall is excessively thick. The infrared heater with high penetrative force can heat the inside and outside of preform simultaneously and keep preform in even heating, therefore high shaping quality. What an operator should do during production is just to put heated preform into the blow mold and press the switch, and then computer will take care of the whole procedure.Features1. Special design for PET Gallon Bottle up to 6 Gallon 2. Produce wide mouth jar up to 25 liter with neck size up to 200mm. 3. Using Infrared reheat units to achieve uniform heating throughout the wall of preform 4. Adopt special designed preform heating system to ensure the optimal heating effect for 730g thick-wall preform5. Special designed fan-cooling system in the heating channels to keep the oven with constant temperature and ensure the preform can be heated completely. 6. Water cooling system ensures the quality of preform neck. 7. Up to 90 bottles/hour using one-cavity mold for 5-gallon bottle 8. Use advanced PLC control system with counting function and time-control precision to 0.01second, and a use-friendly panel. 9. Equipped with special designed air storage units 10. Simple installation & startup adjustment

| TYPE | ITEM | UNIT | TECH. DATA |

| TS-20L | |||

| Main Machine | Max.Volume of Product | Gallon | 3-6 |

| Output | pcs/h | 50-180 | |

| Neck Size of Product | mm | <=160 | |

| Useful Area of Mould | mm | 420*660 | |

| Mould Thickness | mm | 350-420 | |

| Mould Stroke | mm | <=350 | |

| Clamping Force | KN | 80 | |

| Stretching Stroke | mm | 530 | |

| Working Pressure | Mpa | <=1.0 | |

| Blowing Air Pressure | Mpa | <=4.0 | |

| Power of Main Blower | KW | 2 | |

| Weight of Main Blower | Kg | 2500 | |

| Measurement of Main Blower | mm | 2800*720*2160 | |

| Preheater | Power of Preheater | KW | 16 |

| Weight of Preheater | Kg | 800 | |

| Measurement of Preheater | mm | 2200*750*1880 |

You may also like

Send inquiry

Send now